Treehouse Foods in Tonawanda, New York relies on consistent cooling to keep production running smoothly. Inside a bakery environment, temperatures rise quickly. Proper cooling helps maintain the right mixing conditions for their products and creates a safer workspace for their employees. Our team worked to install necessary upgrades that support both needs.

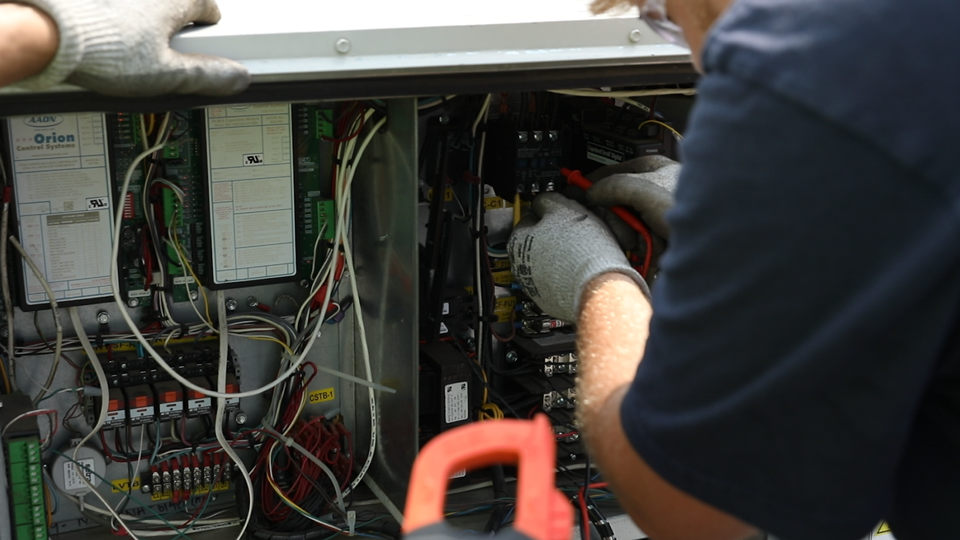

We replaced two rooftop units that played a major role in keeping their facility stable. The work included new gas piping and insulated ductwork that strengthened reliability across the plant. These improvements helped Treehouse maintain the cooling their process demanded during high-production periods.

Building on a Trusted Partnership

Treehouse began as a service customer and eventually moved into a full guaranteed service agreement with our team. That agreement allowed us to manage their mechanical systems with confidence and respond quickly when their operation needed support. As the relationship grew, they brought us in for larger project work, including the upgrades completed during this phase.

Our technicians understood how important dependable cooling was for a food processing environment. Every improvement we made was designed to support quality, consistency and comfort throughout their facility.

A Commitment to Their Entire Operation

Treehouse Foods trusted us to cover their full facility, and we took that responsibility seriously. By investing in updated equipment and better insulation, they improved working conditions for their employees and protected the integrity of their product.

We are proud to stand behind them as a long-term partner. If your facility needs reliable mechanical support or proactive upgrades, we are ready to help guide you to the right solution. Contact us today to learn more about how we can support your operation.