The Cummins Jamestown Engine Plant produces 12- and 15-liter diesel and natural gas engines for heavy-duty applications. Their testing process ranges from a few hours to several thousand, placing demanding requirements on every system in the facility. To meet these challenges, our team works closely with Cummins to provide installation, upgrades and preventative maintenance that keep operations running without interruption.

Tackling Complex HVAC Projects

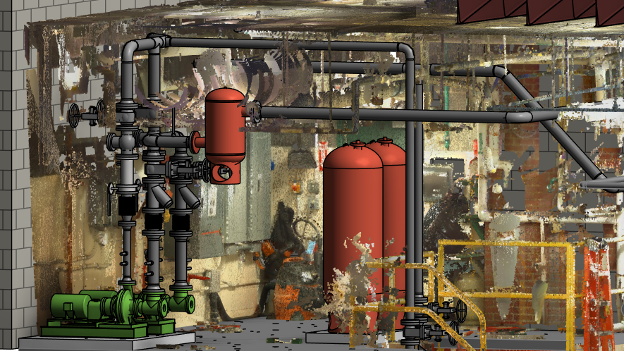

One of the current projects with Cummins involves replacing ventilation equipment in their test cells. The existing system dated back to 1976, with decades of additional layers built around it. Removing that equipment without disrupting production required both technical and financial insight. By partnering early with Cummins engineers, we developed a plan to remove, replace and modernize the system while ensuring operations continued without downtime.

Knowledge That Builds Confidence

Our long-standing relationship with Cummins has given us a deep understanding of their plant and processes. That knowledge helps us specify, design and install equipment that meets their exact needs. Beyond installation, our preventative maintenance program ensures each system is supported for the long run. This proactive approach reduces costs, extends equipment life, and creates peace of mind for their team.

A Full-Service HVAC Partner

For Cummins, knowing that we are only a call or email away makes all the difference. Quick response times, dependable expertise and a commitment to their success define the partnership we share. As their operations continue to evolve, our role is to provide the service and support they can count on to keep engines moving through production with confidence.

Contact us today to discover how Mazza Mechanical can help your facility.