Alkegen’s manufacturing facility in Tonawanda is a high-demand environment producing ceramic fiber for industries like aerospace and automotive. With electrical cabinets, RF ovens and specialized equipment running nonstop, their team depends on systems that stay cool and efficient at all times. That’s where we come in.

Keeping Equipment Cool and Consistent

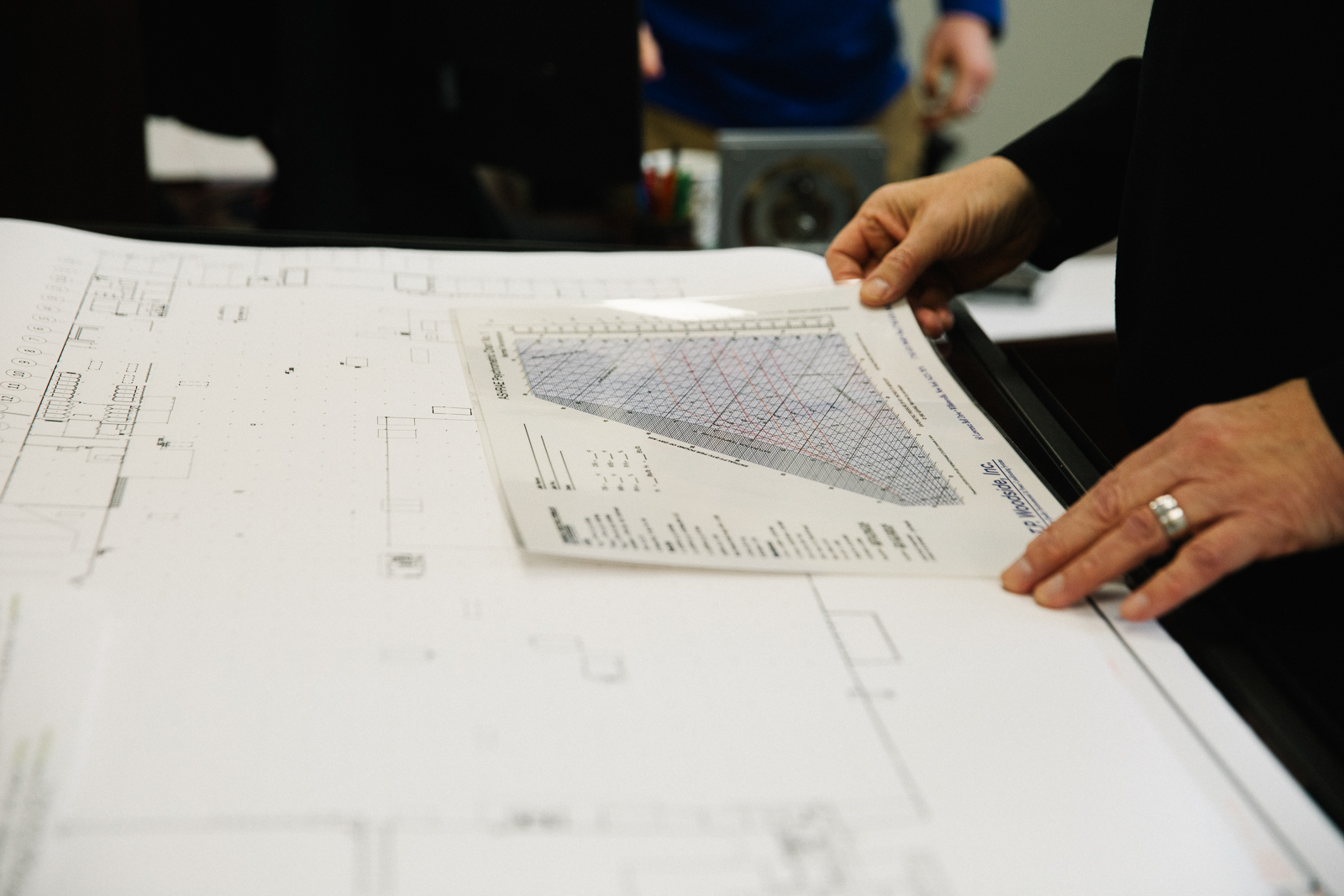

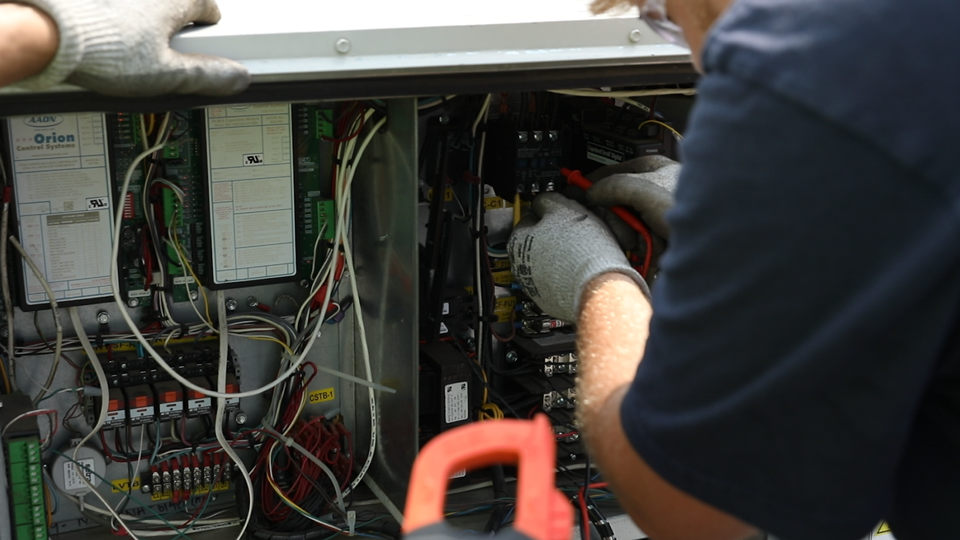

Alkegen uses a unique rotoformer process and cannot risk unexpected downtime. Our preventative maintenance program helps keep temperatures steady and equipment performing as designed. With regular service on cabinet coolers and RF ovens, our team prevents overheating and protects production schedules. As Alkegen shared, they have gone months without failures thanks to the service plan and our dedicated technicians.

Peace of Mind for Their Team

The Alkegen crew describes our approach as hands off and dependable. We handle maintenance with clear communication and safe practices, including lockout tagout procedures. This allows their leadership to focus on their own responsibilities instead of worrying about their mechanical systems. They trust our team to show up on time, follow safety rules and communicate every step of the way. That trust is something we take seriously.

A Reliable Partner

Hearing Alkegen recommend us to other manufacturers speaks volumes about our commitment. They appreciate our professionalism, consistency and quick response whenever a need comes up. We value this partnership and are proud to help them keep operations moving 24/7 without costly interruptions.

If your facility could benefit from the same peace of mind and uptime as Alkegen, explore our preventative maintenance programs! Our team is ready to support your success with reliable service and quality you can count on.