Our team at Mazza Mechanical recently completed a large-scale chiller installation for Han-Tek, delivering a cooling system designed for consistency, dependability and long-term performance. This project required more than equipment placement. It demanded careful planning, precise execution and a deep understanding of how the system would operate under daily production conditions. The result is a solution built to perform when it matters most.

Focused on Efficiency and Reliability

From the earliest planning stages, efficiency and reliability guided every decision. The chiller system was selected and installed to support Han-Tek’s operational needs while minimizing downtime and maximizing energy performance. Every connection, control and component was installed with accuracy to ensure smooth operation from day one. This attention to detail helps protect equipment, stabilize processes and reduce the risk of future disruptions.

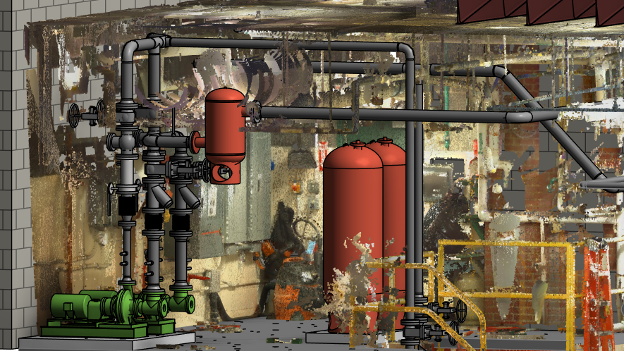

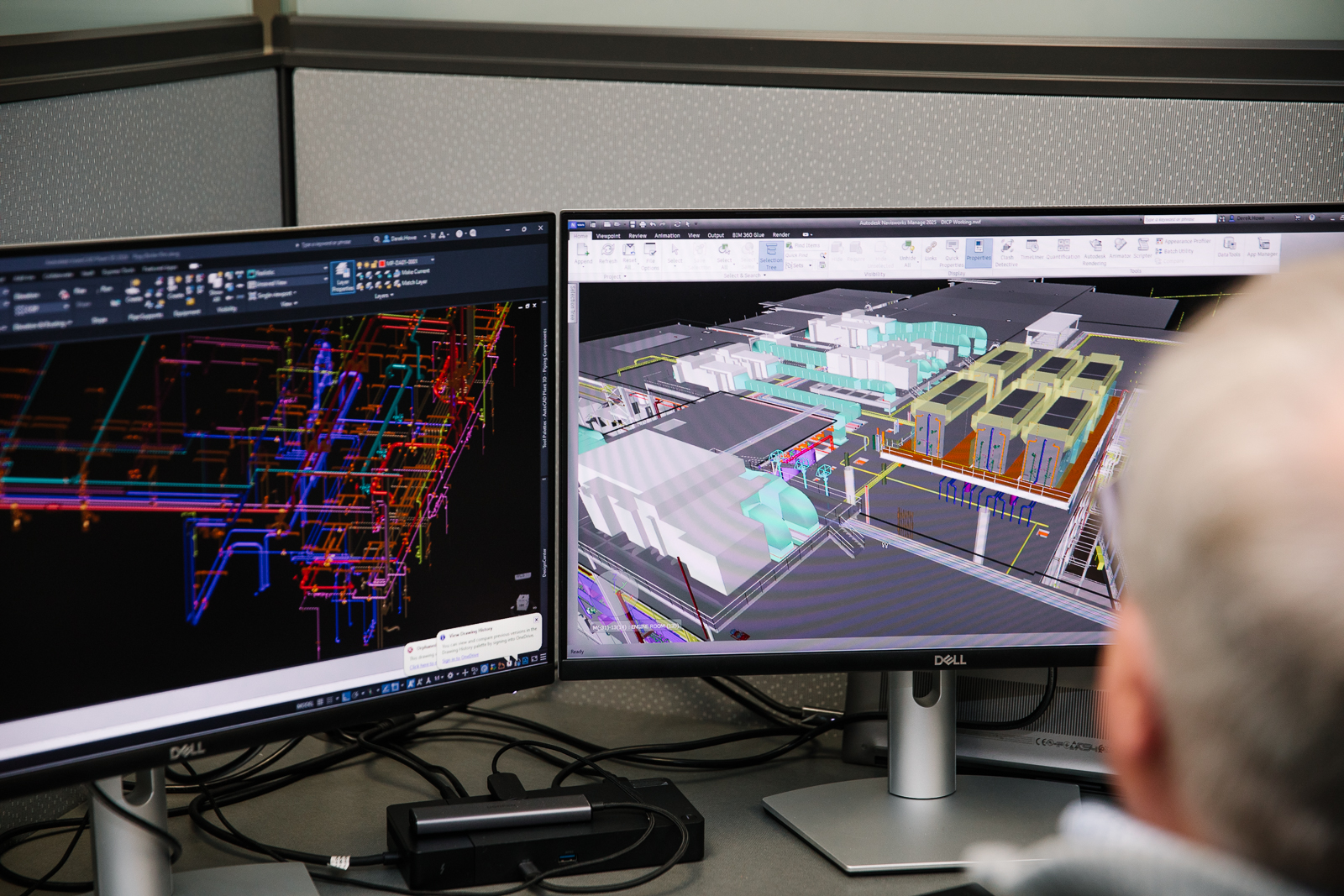

Precision Installation from Start to Finish

Large-scale chiller projects require coordination across multiple trades and tight adherence to specifications. Our team approached the installation with a clear plan and a commitment to precision. Equipment placement, piping and system integration were executed to meet design requirements and jobsite conditions. The goal was a clean installation that supports easy maintenance and long-term serviceability.

Delivering Long-Term Value

This project reflects our approach to mechanical systems that are built for longevity. The chiller installation for Han-Tek provides consistent cooling and dependable operation while supporting future growth. By focusing on quality workmanship and proven solutions, the system is positioned to deliver reliable performance for years to come.

Mazza Mechanical takes pride in delivering mechanical solutions that stand up to real-world demands. The successful completion of this large-scale chiller installation reinforces our commitment to building systems that work efficiently today and continue performing tomorrow.