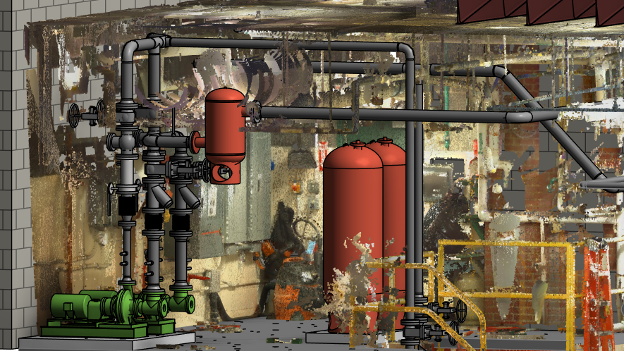

Every industrial project comes with its own unique set of challenges, and the Cummins mist collection project was no exception. The equipment had already been selected, but the real task was designing a system that could work seamlessly with existing cranes, platforms and utilities. Our goal was to ensure efficiency without sacrificing performance, while maintaining the proper velocities and pitch needed to direct mist toward the collector.

Adapting to Change

Industrial environments are always evolving, and adjustments are a natural part of the process. We know unexpected bumps in the road will come, but our team is committed to addressing them quickly. For Cummins, that meant taking extra steps to adapt when conditions shifted. We view these moments not as setbacks but as opportunities to problem-solve and deliver results that stand the test of time.

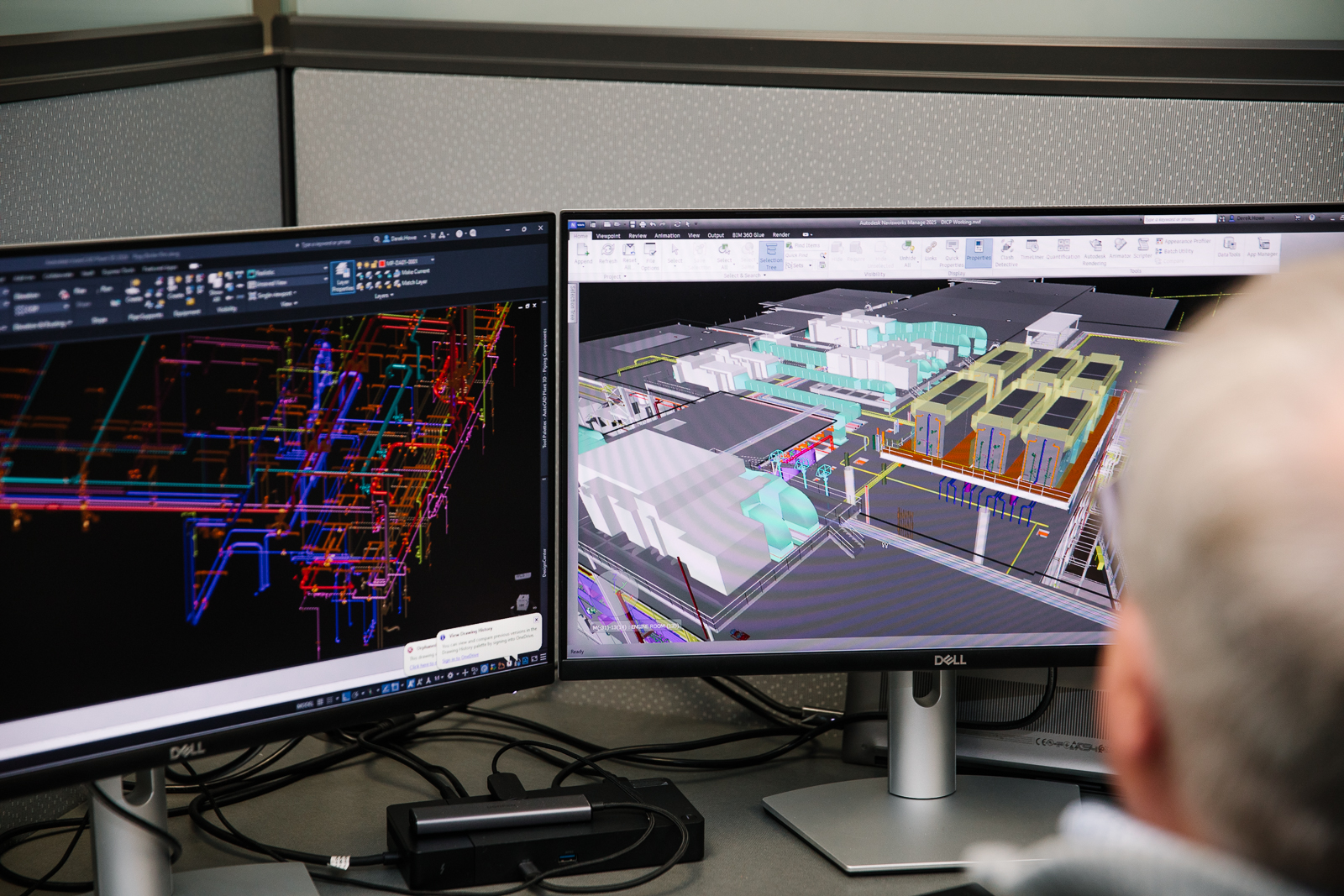

Using Tools to Stay Ahead

Preparation played a major role in the success of this project. With models, three-dimensional drawings and careful planning, we were able to anticipate challenges before they became obstacles. This proactive approach allowed us to make offsets more easily and keep progress moving forward.

Focused on Dependable Results

Our work with Cummins reflects the heart of what we do best—finding solutions and creating dependable outcomes for our clients. From design adjustments to on-site execution, we guided this project with precision and care. The result was a mist collection system that performs reliably while supporting the larger facility operations.

At Mazza Mechanical, we bring the same level of dedication to every project. By combining preparation, adaptability and a focus on solutions, we continue to build strong partnerships and deliver results our clients can trust.