At Mazza, we’re always ready to tackle large-scale projects, and our recent work at Sumitomo Rubber exemplifies our commitment to efficiency and reliability. For this project, we utilized a helicopter to manage equipment installations across Sumitomo’s massive 2.5-million-square-foot plant. A traditional crane was simply not practical for a facility of this scale, so we opted for an aerial approach. This helped us work with both ground and roof crews to ensure flawless coordination.

Seamless Execution by Our Operations Team

Executing a project of this magnitude requires meticulous planning and a dedicated team. Our operations team was fully aligned with our goals, ensuring that each component, from structural steel to roof curbs, was pre-staged for smooth installation. With coordinated efforts from both ground and roof teams, we achieved efficient, timely installation, maintaining safety and minimizing disruptions.

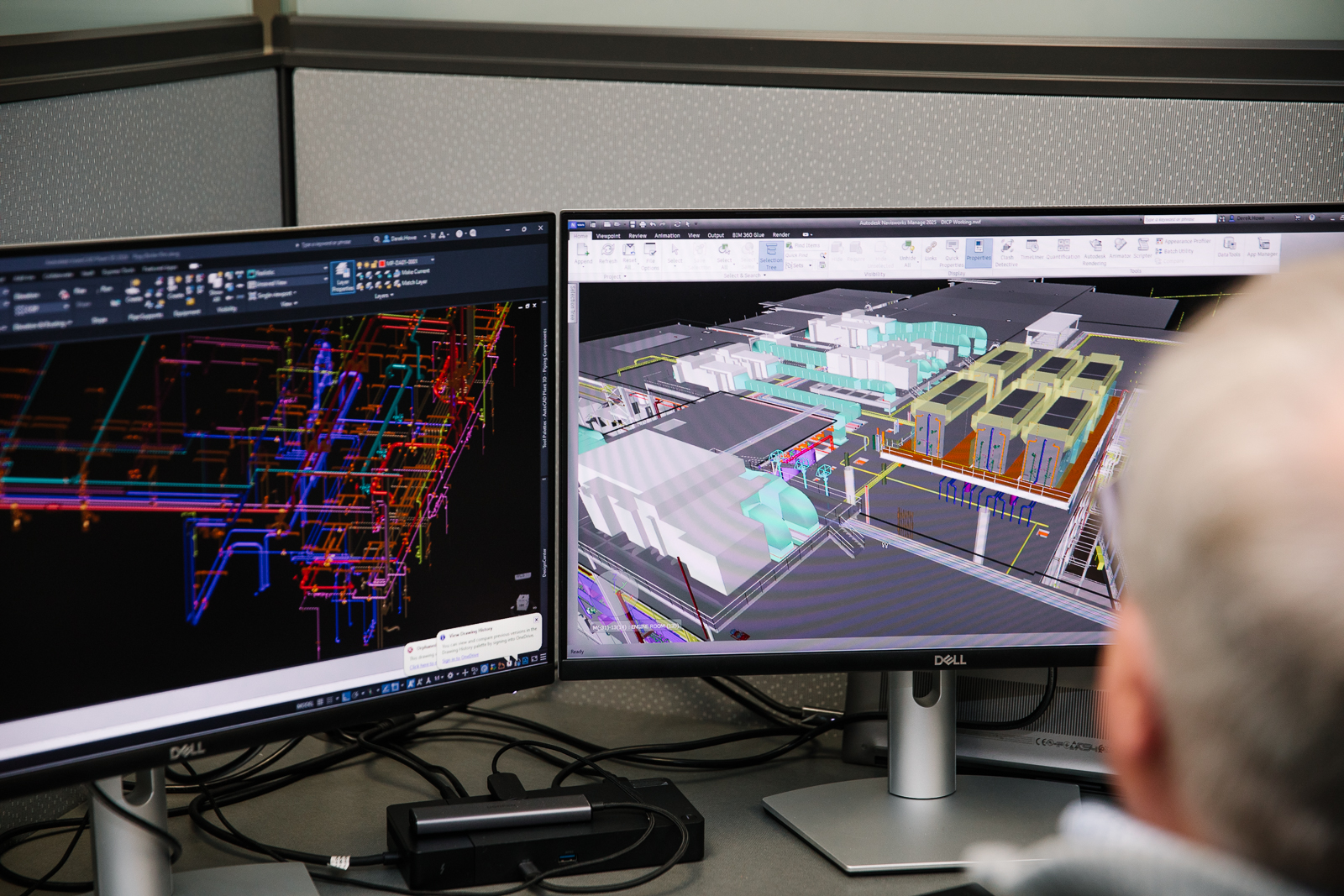

Building Automation for Maximum Efficiency

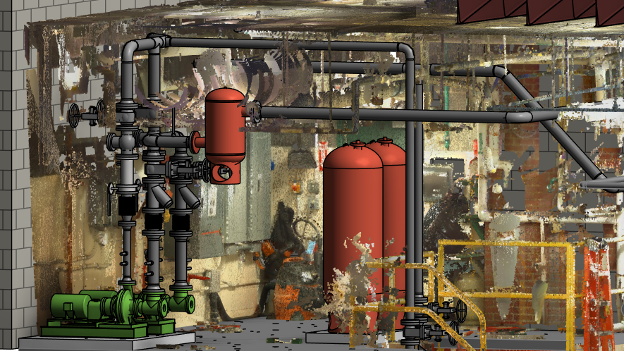

In addition to the equipment installations, we implemented a building automation system at Sumitomo Rubber, which has since delivered impressive results. The system allows Sumitomo to monitor equipment in real time, providing essential data directly to their computers. Since installation, they’ve experienced almost zero downtime, keeping production consistently on track.

Open Systems for Future-Ready Operations

Our approach emphasizes flexibility and future-readiness. While older proprietary systems limit access, the open protocol of our building automation solution ensures that Sumitomo can work with various vendors and technologies. This adaptability empowers Sumitomo to make efficient, informed decisions, supporting ongoing operations without being locked into outdated systems.

At Mazza Mechanical, we take pride in crafting project solutions that not only meet our clients’ needs but also drive their long-term success.