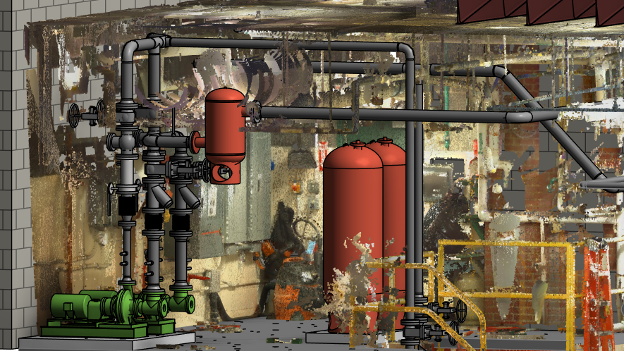

We believe that better planning leads to better outcomes. By using advanced 3D scanning and modeling technology, our team is able to deliver a more accurate, efficient and dependable experience for you and your building. From retrofits in tightly packed industrial facilities to brand-new construction projects, we use every available tool to design mechanical systems that fit seamlessly into the space and meet the demands of the job.

Designing with Accuracy from the Start

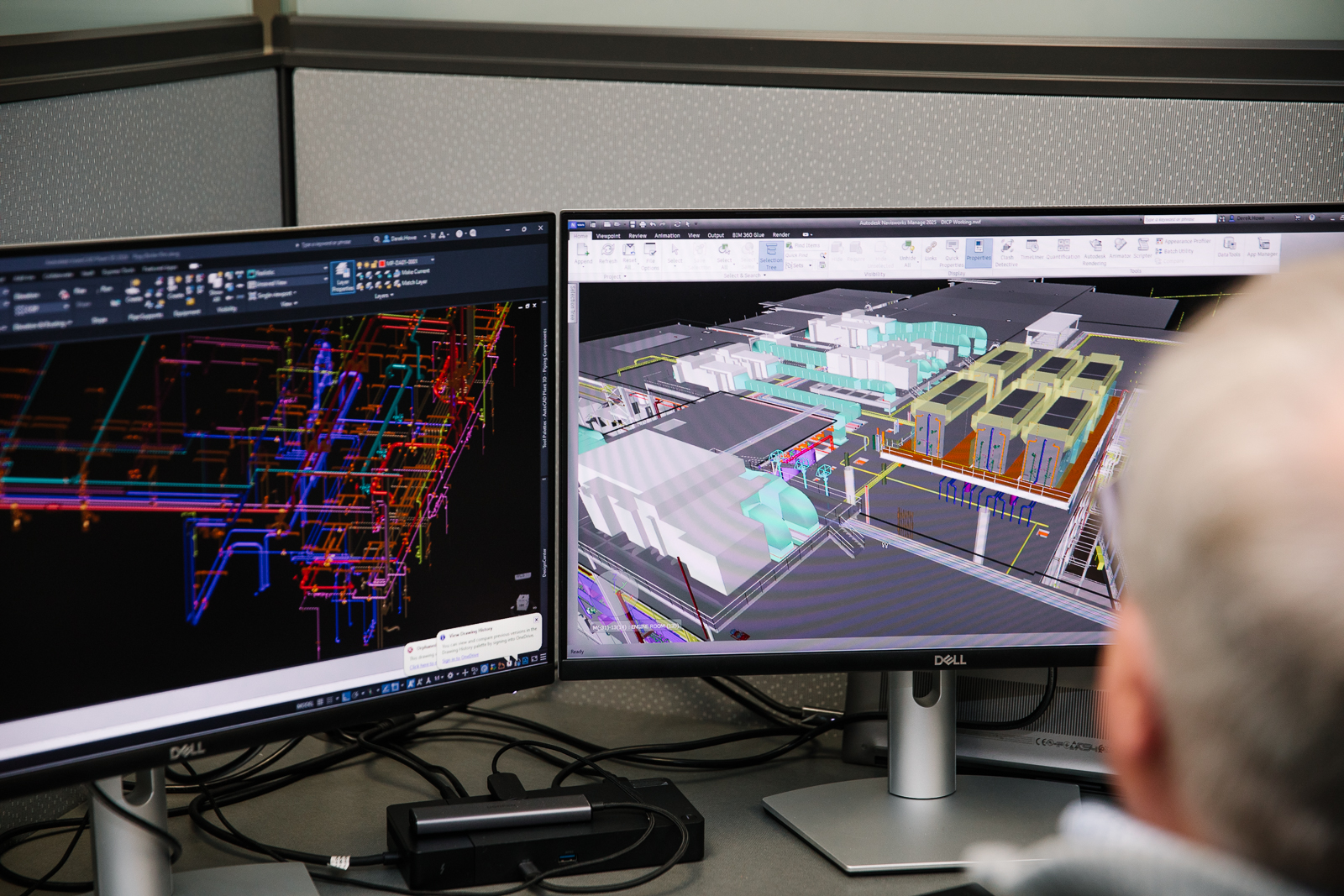

With 3D scanning, we can gather detailed information about an existing building or use modeling software to support architects and engineers on a new design. This process allows us to see the full picture, identify potential conflicts early and coordinate mechanical layouts before construction begins. Instead of reacting to challenges in the field, we can make proactive decisions that keep the project on track.

Reducing Delays with Off-Site Fabrication

Once the model is finalized, our team begins fabrication in-house. In many cases, we’re able to build 40 to 60 percent of the system before stepping foot on the job site. From piping assemblies to spool pieces, we focus on completing as much work as possible in a controlled environment. This approach shortens the installation timeline, reduces on-site labor hours and helps avoid costly interruptions during construction.

A Smarter Way to Build

As a full-service mechanical contractor, we offer comprehensive capabilities across piping, sheet metal and mechanical system design. What sets us apart is the way we use technology and planning to support each project from day one. By combining 3D modeling with off-site fabrication, we’re able to deliver a more predictable process and a better experience. That’s the Mazza advantage, and it’s how we help clients build with confidence.