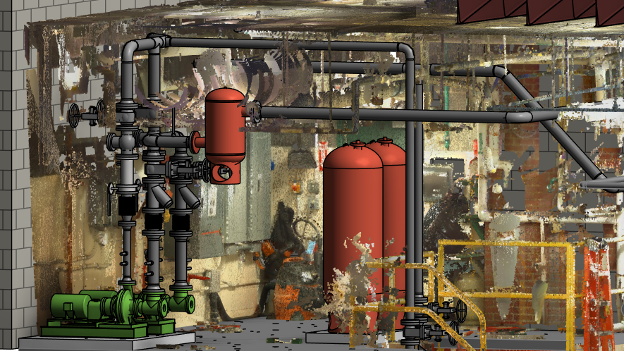

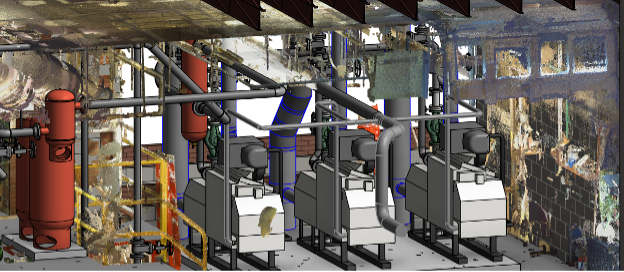

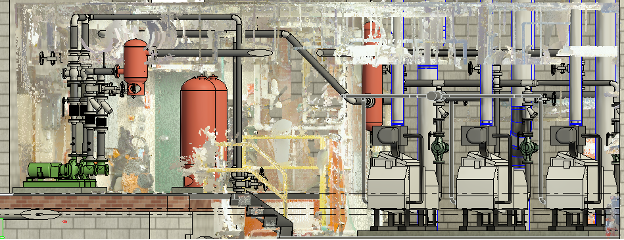

Our team is currently supporting a boiler replacement project for a school district in Pennsylvania, and we’re putting our full design and fabrication process to work. It starts with a detailed 3D scan of the existing boiler room. This initial step allows our design team to model around real-world conditions. It also reduces surprises in the field and increasing overall accuracy.

Once the model is finalized, our in-house fabrication team gets to work building the piping spools. By fabricating off-site, we’re able to shorten the installation schedule and minimize disruption to the school’s operations. It also allows for better quality control and tighter coordination between trades in the mechanical room.

Every boiler room is different, and tight spaces often leave little room for error. That’s why we rely on precise measurements and pre-planned solutions to deliver results that fit right the first time. From start to finish, this method helps improve safety, reduce rework and keep projects moving forward on time and within budget.

This project is just one example of how smart planning and fabrication come together to make mechanical upgrades more efficient. We’re proud to bring our expertise to every phase—design, fabrication and installation—so our clients can count on lasting performance when it matters most.